Application of heating furnaces

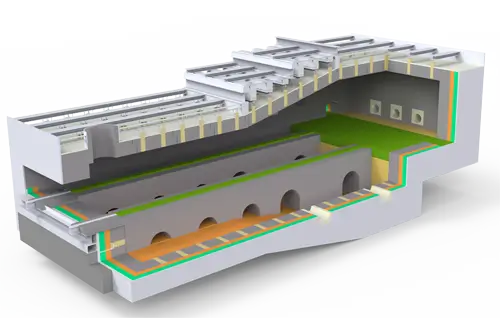

Refractory insulation coating to prevent cracking of heating furnace refractory materials. Heating furnaces are used in petroleum, chemical, metallurgical, mechanical, building materials and other industries. Heating furnaces are essential equipment in the process of oil field development.

Types of refractory materials

Refractory insulation coating to prevent cracking of heating furnace refractory materials. Commonly used refractory materials for heating furnaces are: alumina cement, low cement, phosphate, mullite, refractory bricks, other refractory materials include refractory fiber, plastic, etc.

Causes of cracking of refractory materials

The characteristics of alumina cement are high hydration heat, fast setting speed, high early strength, good heat resistance, corrosion resistance, impermeability, and freeze-thaw resistance. Mullite refractory raw materials have the characteristics of uniform expansion, excellent thermal shock stability, high load softening point, small high temperature creep value, high hardness, good chemical corrosion resistance, etc. At present, there are mainly high-purity fused mullite, ordinary fused mullite, all-natural bauxite concentrate sintered mullite and lightly burned mullite.

Refractory bricks are a type of building material bricks, and their properties are the same as their name “refractory”. Refractory bricks have good earthquake resistance; Refractory bricks have good wear resistance and impact resistance; Refractory bricks can resist the erosion of slag at high temperatures, and can also withstand shear and other pressures. When the boiler is running, the above refractory materials will crack and be damaged when the temperature rises too fast and in the case of rapid cooling and heating, resulting in the boiler not being able to be used normally. Apply LHY-1201 refractory insulation coating. This product is composed of high-temperature adhesives, nano high-temperature ceramic microbeads, various high-temperature fillers, and special additives. It can work in a high-temperature environment below 2000℃ for a long time, and insulate the equipment. The instantaneous working temperature can reach 2000 degrees. It has many advantages such as waterproof, fireproof, anti-corrosion, wear-resistant, and insulation.

The coating uses nano-ceramic technology, and the insulation efficiency can reach more than 80%. The coating can be applied to all inorganic materials, such as metals, bricks, concrete, wood blocks, glass fibers, castables, refractory materials, etc., and the coating is non-flammable and has a fireproof grade of A. Applying this coating can prevent condensation. There are no harmful substances, VOCs and other ingredients, and it will not cause harm to the human body during construction and use. Insulate high-temperature equipment, reduce fuel and energy consumption, and at the same time, because the surface temperature of the equipment is lowered. The coating has been successfully used for thermal insulation of some high-temperature equipment such as aviation, metallurgy, textiles, steelmaking, cement manufacturing, thermal power generation, and new energy power generation, such as furnaces, high-temperature steam pipes, high-temperature chimneys, high-temperature flues, high-temperature hot gas pipes, various molds, heat exchangers, dye vat insulation, etc. The coating is applied to the inner walls of various heating furnaces, such as ceramic fiber linings, which can extend the service life of ceramic fibers by about 50% and prevent the fiber lining from falling off. The coating is applied to the castable lining and refractory brick lining of the inner wall of the heating furnace, which can extend the service life of the lining by 50% and prevent the lining of refractory bricks from cracking after long-term high-temperature sintering.

Reheating Furnace