Refractory materials are classified into neutral, alkaline and acidic. Whether it is refractory bricks or refractory castables, these three properties are also used to distinguish them.

Neutral refractory materials are composed of alumina or carbon. Products include high-alumina, corundum, and carbon refractory bricks and castables.

Acidic refractory materials are composed of silicon oxide. Products include siliceous and clay refractory bricks and castables, such as silica bricks, lightweight silica bricks, acid-resistant bricks, clay bricks, acid castables, and acid lightweight castables. Acidic products are mainly used for the lining of coke ovens, glass melting furnaces, etc. Clay bricks are weakly acidic, but have good thermal shock resistance and are the most widely used.

Alkaline is a refractory material with magnesium oxide and calcium oxide as the main components. The products include magnesium bricks, straight magnesium bricks, magnesium aluminum spinel bricks and amorphous castables containing 80-85% magnesium oxide or more. Alkaline materials have strong resistance to slag and iron, and the acidic refractoriness is higher than that of neutral products. Alkaline products are mainly used for kiln linings in alkaline atmospheres, such as rotary kilns and converters. Magnesium dolomite refractory bricks in alkaline refractory materials are strongly alkaline, and chromium-magnesium and forsterite refractory bricks or castables and spinel composites belong to weakly alkaline refractory materials.

Neutral, alkaline and acidic are mainly distinguished by the main components of the matrix. Acidic refractory materials contain a certain amount of silica. Strongly acidic refractory materials are silica bricks and silica castables, which are composed of 94-97% silicon (SiO2). Compared with silica, clay refractory materials have less silicon content (SiO2) and are weakly acidic. Semi-siliceous materials are also in the middle.

Among the neutral materials, high-alumina bricks, corundum bricks, high-alumina castables, corundum castables, and mullite castables are neutral materials with an aluminum content higher than 45%. Chromium refractory materials are also alkaline and neutral refractory materials.

All raw materials in refractory materials are basically natural minerals, and they are processed into refractory bricks or castables of different grades according to the grade of the raw materials, so no matter what kind of properties, they are of different qualities.

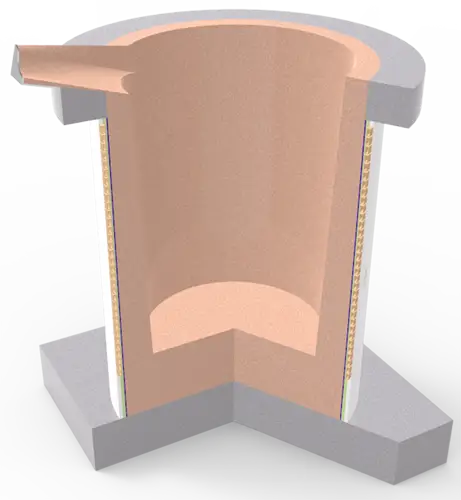

Induction Furnace

What are the advantages of acidic refractory materials

Acidic refractory is a kind of special refractory used in high temperature environment, mainly made of silicate, alumina, boric acid and other substances. Compared with other types of refractory materials, acidic refractory has the following advantages.

- Good acid corrosion resistance: Acidic refractory uses silicate as the main raw material, so it has excellent corrosion resistance in acidic environment. For example, in industrial fields such as copper smelting and zinc smelting, acidic refractory is widely used in the lining of equipment such as electrolytic cells.

- Strong stability: Acidic refractory has high chemical stability and can maintain stable physical and chemical properties even in high temperature and acid corrosion environment, thereby extending its service life.

- Good thermal conductivity: Due to the high content of alumina in acidic refractory, its thermal conductivity is very good, which can help improve the heat transfer efficiency and thermal stability of equipment.

- Strong construction flexibility: The preparation process of acidic refractory is relatively simple, and it can be constructed by pouring, spraying, masonry and other methods, and the proportion and performance of the material can be adjusted according to specific needs.

Advantages of basic refractory castables

Magnesium refractory castables are made of fused magnesia or sintered magnesia aggregate and fine powder, and the binder is periclase cement, magnesium chloride, magnesium sulfate, water glass, polyphosphate, etc.

- Magnesium refractory castables

Magnesium castables with periclase cement as binder have the characteristics of high purity, small linear change after burning, and high load softening temperature. Magnesium castables with water glass as binder have the advantages of high strength and strong resistance to alkali and sodium salt melt corrosion. Magnesium castables combined with polyphosphate have the characteristics of high load softening temperature, high strength, and excellent thermal shock resistance.

- Magnesium-aluminum refractory castables

Magnesium-aluminum refractory castables are made of fused magnesia, sintered magnesia, fused or sintered spinel, fused corundum, alumina powder, high alumina powder, and the binder is water glass, silicon oxide and alumina powder, calcium aluminate cement, phosphate, etc. In high-temperature use, the main crystal phase is alumina-magnesia spinel, which is easy to expand and micro-crack, can buffer the thermal stress inside the castable, has good thermal shock resistance, and has a strong anti-penetration effect on slag.

- Magnesia-silica castable

Magnesia-silica refractory castables include castables made of forsterite and castables made of magnesia sand and silica powder. Castables made of magnesium oxide and sio2 micropowder have the characteristics of good construction performance and low water consumption. When 12% of silicon powder is added to the refractory castable, an alkaline castable with no residual shrinkage can be made. As the sio2 content increases, the degree of erosion of the castable by the slag increases, but the penetration depth continues to decrease.

- Magnesia-chromium refractory castable

Magnesia-chromium refractory castables include castables made of fused magnesia sand or waste magnesia-chrome brick sand and fine powder, and castables made of magnesia sand, chromite or chromium oxide. The binder mainly uses polyphosphate, calcium aluminate cement, binder clay, oxide ultrafine powder, etc. Magnesium-chromium refractory castables have the advantages of high use temperature, good high temperature volume stability, strong resistance to slag erosion, etc. After reading its four categories and characteristics, we will get to know its uses.