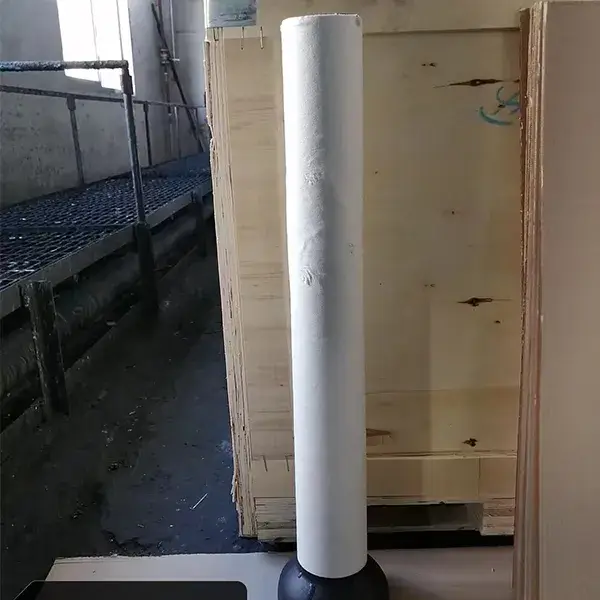

Long Nozzle

Long nozzle: During continuous casting, the long nozzle connects the ladle to the tundish. Its function is to block air during molten steel pouring, preventing secondary oxidation and nitrogen absorption, while also curbing molten steel splashing and slag entrainment. As molten steel rapidly flows through the nozzle, it must exhibit excellent thermal shock resistance, impact resistance against molten steel, and slag erosion resistance.

Common materials for long nozzles include fused quartz, Al₂O₃-C, and ZrO₂-C. Fused quartz nozzles are inexpensive but exhibit poor resistance to molten steel erosion and to attack from ladle coverings and molten slag. Al₂O₃-C nozzles offer extended service life and strong adaptability to various steel grades; while ZrO₂-containing nozzles are relatively expensive, typically employing ZrO₂-C materials only at the slag line section.

Submerged Nozzle

Immersion nozzle: The molten steel flows from the ladle to the mold through an immersion nozzle, which controls the flow state and pouring speed of the molten steel. It prevents secondary oxidation of the molten steel and the entrainment of mold protective slag into the molten steel, promotes the flotation of inclusions, and ensures uniform thermal flow distribution across the cross-section of the ingot within the mold.

The slag line of the submerged nozzle requires excellent resistance to protective slag erosion, while the body demands thermal shock resistance, erosion resistance, and prevention of Al₂O₃ adhesion that could block the nozzle. Therefore, the nozzle body uses Al₂O₃-C material, and the slag line section employs ZrO₂-C material.

To address the needs of special steel grades, various materials for submerged nozzles have been developed. For example: ZrO₂-CaO-C system, carbon-free Al₂O₃-SiO₂ system, and MgO-CaO-C system submerged nozzles effectively resolve nozzle flocculation blockage during casting of low-carbon aluminum-killed steel; MA-C type submerged nozzles are suitable for high-oxygen steels. To support the development of quick-change technology for slab continuous casting submerged nozzles, a high-wear-resistant, high-oxidation-resistant, low-carbon Al₂O₃-C facing material has been developed.

Monoblock Stopper

Plug Rod: The flow of molten steel from the ladle to the mold is controlled by the integral plug rod, which can also be used to inject inert gases such as argon into the molten steel. Since it must control both pouring initiation and termination, the plug rod head must resist erosion and work effectively with the submerged nozzle. Additionally, the slag line must possess excellent erosion resistance to withstand the erosion from ladle slag.

The plug rod is primarily made of Al₂O₃-C material. To ensure reliable performance and sustained flow control during use, the plug head typically employs low-carbon material with a carbon content not exceeding 15% by mass, guaranteeing excellent resistance to molten steel erosion. The plug body generally uses high-carbon material with a carbon content not less than 26% by mass. The slag line section incorporates MgO-C or ZrO₂-C material to enhance the overall erosion resistance of the plug. For low-carbon steel and high-manganese steel applications, the plug head material should be Al₂O₃-MgO-C (corundum-spinel) composition.

To meet the specialized functional requirements of high-purity steel continuous casting production, multi-furnace continuous pouring, and continuous casting production technology, the three major components of continuous casting will continue to evolve toward low pollution, extended service life, and multifunctionality.

The three major components of continuous casting are indispensable key materials for achieving and ensuring normal continuous casting production in steel mills. They provide crucial support for efficient continuous casting and near-final-shape continuous casting to produce high-quality, high-value-added clean steel.

To reduce costs and lower consumption, steel mills are striving to increase continuous casting furnace cycles, thereby placing higher demands on the three major components of continuous casting. What measures have refractory plants taken to meet these needs?

The primary measures adopted are as follows:

(1) For the three major components of continuous casting (long nozzle, integral stopper, ladle top nozzle, and submerged nozzle), we have developed new formulation materials with enhanced resistance to molten steel and slag erosion. This was achieved by thoroughly investigating the failure mechanisms observed in different customer applications and developing targeted solutions. Examples include low-carbon nozzle materials for high-oxygen steel casting, magnesium-carbon and spinel-carbon nozzle materials for high-calcium, high-manganese steel casting, and magnesium-carbon and zirconium-carbon materials for long nozzles and plug rod slag lines in high-alkalinity ladle coverings.

(2) By studying the temperature fields, stress fields, and molten steel flow fields experienced by products during use at different customer sites, we have optimized the structural design of the three major components for continuous casting, enhancing product reliability and service life.

(3) For specific casting environments—such as steels prone to severe flake formation during casting (e.g., Al-killed steels, titanium- or cerium-containing steels)—develop specialized anti-flake materials and design various anti-flake structures to extend continuous casting furnace life and reduce refractory consumption.

Does the application of high-alkalinity protective slag have an impact on the three major components of continuous casting? How can molten steel cleanliness be ensured during the continuous casting process?

High-alkalinity protective slag may exacerbate erosion of traditional aluminum-carbon materials to some extent. However, as long as the turbulent energy at the ladle liquid surface is properly controlled, this effect is not severe enough to impact continuous casting furnace cycles.

Ensuring molten steel cleanliness is a systematic endeavor, with the three major components of continuous casting playing only a minor role. Specifically, their contribution manifests in the following aspects:

(1) Sealing at the long nozzle bowl opening. Refractory manufacturers should prioritize designing the bowl opening with highly oxygen-resistant materials to ensure excellent argon sealing performance and minimize secondary oxidation of molten steel.

(2) All three major components must exhibit sufficient resistance to molten steel erosion. This means minimizing the erosion rate per unit time at the steel-refractory interface, thereby reducing potential contamination from the refractory materials.

(3) Functional structural designs, such as the plug rod, tundish nozzle, and submerged nozzle argon-blowing mechanisms, also contribute to molten steel cleanliness through optimization.

What areas for improvement remain in the technological direction of the three major components of continuous casting?

There is still significant room for improvement in the technical aspects of the three major components of continuous casting.

Regarding the material of the stopper head, the traditional stopper head material is Al-C, with an Al₂O₃ content of approximately 78%. The long-life stopper head we have developed achieves an Al₂O₃ content exceeding 80% and exhibits superior thermal stability. Depending on steel grades, plug head materials include magnesia plug heads, spinel plug heads, magnesia-alumina spinel plug heads, aluminum-zirconium-carbon plug heads, zirconia plug heads, and high-alumina plug heads. Zirconia plug heads are costly but can be used for composite layers.

Reinforced slag lines for plugs can be made of high-alumina or magnesia materials.

Permeable ladle nozzles can be designed as dispersed or directional types to enhance molten steel purity and improve billet quality.

For submerged nozzles, appropriately increasing zirconium content in the slag line enhances density while maintaining thermal stability, thereby improving compressive strength and flexural strength. Optimizing additive types and dosages, refining raw material particle size distribution, and refining formulations collectively enhance erosion resistance and thermal stability.