The roof of a steel rolling heating furnace can be divided into two types: arched roof and flat roof. The arched roof is built with refractory bricks. Generally, the inner layer is a 232mm or 300mm thick refractory brick layer, and the outer layer is covered with an insulation layer. This type is only used in small furnaces with a furnace width of less than 3m. Large furnaces all adopt flat roofs. The earlier flat roof was hung with special-shaped refractory bricks, but since the promotion and use of amorphous refractory materials, the roof of a steel rolling heating furnace has almost all been made of refractory castables or refractory plastics.

There are two typical refractory castable roof structures. One is an integral casting structure. During construction, the formwork is first supported and the anchor is fixed to the furnace roof steel structure, and then the refractory layer is cast, and the expansion joint is left; the insulation layer above the refractory layer uses lightweight castables. The second type is the prefabricated block structure, which appeared in the early days of the use of amorphous refractory materials. Its advantage is that it is easy to construct and maintain, but it uses a lot of materials and the furnace top insulation is not good. It has gradually been replaced by the integral cast structure.

1.Application of refractory materials in heating furnaces

The application of refractory materials in regenerative heating furnaces has been quick-drying castables, quick-drying self-flowing castables and quick-drying slag-resistant castables for heating furnaces since the late 1990s. These materials not only ensure the excellent performance of low-cement, ultra-low-cement and cement-free castables, but also can be quickly constructed, especially can be quickly baked, so that the furnace body of the integral castable can be baked within 3 to 5 days. In addition to the above characteristics, quick-drying slag-resistant castables also have excellent anti-oxidation iron sheet erosion properties.

2.The development of heating furnace

The regenerative heating furnace is a new type of heating furnace developed in recent years. The biggest feature of the regenerative heating furnace is high efficiency and energy saving. The average energy saving rate is increased by 30% on the existing basis, and the pollutant emissions, especially NOx emissions, are reduced. Therefore, this type of heating furnace has received great attention from the metallurgical industry.

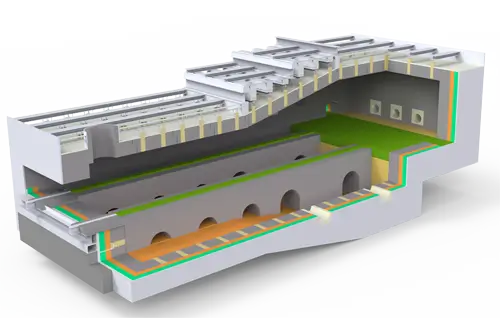

There are three main types of regenerative heating furnaces: channel heating furnaces, external regenerative heating furnaces and burner heating furnaces. Compared with general heating furnaces, the combustion method, heat exchange method, heat exchange medium and other aspects of the regenerative heating furnace have undergone major changes, and the furnace structure has also changed.

There are many mutually isolated regenerators and many crisscrossing gas or air pipes in the furnace body of the channel heating furnace. The regenerator casted with traditional vibration molding castables has the disadvantages of decreased strength at medium temperature, large linear shrinkage, poor volume stability, etc. due to the unreasonable gradation of ordinary refractory castables and the use of cement. After a period of use, it is easy to crack, causing the regenerator to leak during operation, affecting the heat exchange and energy saving effect. In particular, once the gas regenerator leaks, it will bring safety hazards to production. Ordinary castables use vibration equipment to make the material flow during construction to achieve the required filling effect, but in the narrow and complex shape of the regenerator furnace wall (the furnace wall is a multi-layer structure, layered construction, and the thickness of each layer is only about 100mm), the vibration equipment cannot be used. The use of self-flowing castables can solve this problem well.

3.Application of Castables

Self-flowing castable is a low-cement or ultra-low-cement refractory castable that can flow, form, level and degas without vibration. Suitable raw materials and particle size grading are selected for different use parts, and composite ultrafine powder and high-efficiency dispersant are used to obtain better construction performance and high-temperature use performance. Self-flowing castable is suitable for narrow and complex construction parts, such as the wrapping of the bottom water pipe of the steel rolling heating furnace, the furnace wall of the heat storage heating furnace with special structure, and it is also convenient to use self-flowing castable for some parts that need local repair and filling.

Quick-drying self-flowing castable is used for water-cooling pipe wrapping. The water-cooling pipe wrapping part has a small material thickness, generally 40 to 60 mm. If castable is used, it is difficult to vibrate fully, which affects the integrity and strength of the material. The use of quick-drying self-flowing castable can not only fill the material by itself and make it dense, but also ensure the integrity and strength of the material, and it is easy to construct and bake.

More details about Reheating Furnace

What is the temperature of a reheating furnace?

The purpose of a slab reheating furnace is to heat steel slabs to a suitable temperature profile (around 1250°C) before entering to hot rolling phase. The reheating furnace is divided in zones, each zone being controlled independently.

What are the components of a reheating furnace?

Key components of a reheating furnace include the combustion system (burners, fuel lines), the furnace chamber (lining, insulation), charging and discharging systems, temperature sensors, control panels, and flue gas exhaust systems.

What type of burner is used in reheating furnace?

Regenerative Burners for Reheating Furnaces. A regenerative burner is a heat recovery system that recovers the waste heat of the furnace exhaust gas to heat-up the combustion air of the furnace. The regenerative burner uses heat reservoirs and dual heat-recovering generators at each burner.

What is a reheating furnace used for?

Reheating furnaces are a critical component of the steelmaking process. These furnaces are used to heat steel ingots, billets, or slabs to a high temperature, making them malleable and easier to shape into the desired form.