Refractory materials refer to inorganic non-metallic materials with a refractoriness of no less than 1580°C. They serve as structural materials for thermal equipment such as high-temperature kilns, as well as materials for industrial high-temperature vessels and components, capable of withstanding corresponding physical-chemical changes and mechanical stresses.

Refractory materials are high-temperature structural materials manufactured from natural ores such as bauxite, silica, magnesite, and dolomite through processing. Beyond natural raw materials, refractories increasingly utilize industrial feedstocks and synthetic materials like mullite, spinel, and silicon carbide. Significant advancements have also been made in refractories for smelting pure metals or special alloys, as well as for producing oxides and refractory compounds in high-temperature technologies. These developments have created a diverse and complex refractory materials system. Different refractories exhibit distinct compositions, preparation processes, structural characteristics, and performance properties. Even refractories with identical compositions may vary in preparation methods and physical forms. Therefore, scientific classification is essential for research and rational application. Multiple classification approaches exist based on different perspectives.

1.Classified by composition

Refractories can be classified into siliceous products, aluminosilicate products, magnesia products, dolomite products, chromium products, carbon products, zirconia products, pure oxide products, and non-pure oxide products. This classification method characterizes the fundamental composition and properties of various materials, holding practical significance in production, application, and scientific research. Table 1 lists the various refractory materials classified by chemical composition.

2.Classified by Process Method

Refractory products can be classified into slurry cast products, plastic molded products, semi-dry pressed products, powdered non-plastic rammed products, cast products from molten materials, spray-formed or drawn products, and natural products cut from rock. This classification method clearly illustrates the process characteristics of refractory products.

3.Classified by Refractoriness

Refractory products can be classified into three categories: Ordinary refractory products, with a refractoriness of 1580–1770°C; High-grade refractory products, with a refractoriness of 1770–2000°C; Special-grade refractory products, with a refractoriness exceeding 2000°C. This classification system indicates the high-temperature performance characteristics of refractory materials.

4.Classification of Refractory Materials by Shape

Refractory products can be categorized into shaped refractories, such as fired bricks, fused bricks (cast bricks), refractory insulating bricks, and specialized products like crucibles and vessels for laboratory and industrial use; and unshaped refractories, commonly referred to as bulk materials, which are formed into the required shape and heat-treated at the point of use, including castables, ramming mixes, shot-blasted refractories, sprayed refractories, and refractory mortars. Refractory fibers, such as aluminum fibers and alumina-silica fibers, are typically processed into blankets, felts, boards, ropes, composite components, and fiber block products before use. This classification method clearly reflects the physical form of refractory materials.

1. Silica Refractories

Siliceous refractories refer to refractory materials primarily composed of SiO₂. Major products include silica bricks, unshaped siliceous refractories, and quartz glass products.

Siliceous refractories are typical acidic refractories. Their mineral composition features tridymite and cristobalite as the main crystalline phases, with a quartz glass phase as the matrix. Siliceous refractories exhibit strong resistance to acidic slags but suffer severe erosion from basic slags. They possess high load-bearing softening temperatures, and residual expansion ensures excellent airtightness and structural strength in masonry. They offer good wear resistance and thermal conductivity but have low thermal stability and moderate refractoriness, limiting their widespread application. Siliceous bricks are primarily used in coke ovens, glass melting furnaces, acid steel furnaces, and related thermal equipment.

2. Magnesia Refractories

Magnesia refractories refer to materials primarily composed of magnesite, seawater magnesia, and dolomite as raw materials, with periclase as the main crystalline phase and MgO content exceeding 80% to 85%. Magnesium-based refractories belong to the alkaline refractory category, exhibiting strong resistance to alkaline substance corrosion and exceptionally high refractoriness. They are the most widely used and critical type of refractory in alkaline converters, electric furnaces, iron melting furnaces, and numerous non-ferrous metal pyrometallurgical processes. They are also commonly employed in the high-temperature zones of glass regenerators, cement kilns, and ceramic kilns.

Magnesia refractory products can be broadly categorized into metallurgical magnesia and magnesia-based products. Based on chemical composition and application, they include metallurgical magnesia, magnesia bricks, magnesia-silica bricks, magnesia-alumina bricks, magnesia-calcium bricks, magnesia-carbon bricks, and other varieties. Their properties are significantly influenced by the CaO/SiO₂ ratio and impurities. High-purity magnesia bricks exhibit significantly superior load-bearing softening points and thermal shock resistance compared to standard magnesia bricks. With high refractoriness and excellent resistance to alkaline and iron slags, it serves as a crucial high-grade refractory material. Magnesia products are predominantly manufactured via sintering at temperatures typically ranging from 1500 to 1800°C. Alternatively, chemical binders may be added to produce unfired bricks and unshaped refractories.

3. Cast Refractories

Cast refractories refer to products formed by melting raw materials and batches at high temperatures and then casting them into specific shapes. There are two methods for melting the batch: electric melting and aluminothermic melting. Electric melting involves melting the batch in an electric arc furnace or resistance furnace. Aluminothermic melting utilizes the heat released from the aluminothermic reaction (2Al + Fe₂O₃ → 2Fe + Al₂O₃ + Q) to melt the batch. Electrofusion is currently the primary method for producing cast refractories.

Cast refractory products encompass numerous types, with cast zirconia-alumina bricks being the most widely used today. Other fused cast products include fused cast mullite bricks, fused cast zirconia-mullite bricks, fused cast corundum bricks, as well as magnesia, spinel, and olivine-based fused cast products. Compared to sintered products, fused cast products exhibit the following characteristics: high density with minimal porosity; superior mechanical strength; excellent high-temperature structural integrity; high thermal conductivity; and outstanding slag resistance.

4. Carbon-containing refractory materials

Carbon-containing refractories refer to refractory materials primarily composed of carbides, classified as neutral refractories. They are divided into two categories: carbon products and graphite-clay products.

Carbon-containing refractories exhibit high refractoriness (pure carbon melts at 3500°C, though sublimation begins at 3000°C; silicon carbide decomposes above 2200°C), excellent thermal and electrical conductivity, superior load-deformation temperature and high-temperature strength, and better slag resistance and thermal shock resistance than other refractories. However, products in this category share the common drawback of susceptibility to oxidation.

Carbon-based products are primarily composed of carbon, manufactured using coke, graphite, or heat-treated anthracite as raw materials, with carbon-containing organic materials serving as binders. This category includes carbon bricks primarily composed of coke or anthracite, as well as graphitized artificial graphite and semi-graphite carbon bricks. Carbon-based products exhibit excellent thermal stability, erosion resistance, high-temperature strength, and thermal conductivity at elevated temperatures. They are currently primarily used in blast furnaces.

Graphite-clay products are refractories made from natural graphite with clay as the binder. They exhibit excellent thermal conductivity, high-temperature resistance, inertness toward molten metals, and low thermal expansion. Examples include graphite-clay crucibles, distillation pots, plug bricks for steel casting, nozzle bricks, and ladle lining bricks. Among these, graphite-clay crucibles are the most widely produced and applied in steelmaking and non-ferrous metal smelting.

Silicon carbide products are advanced refractories manufactured from silicon carbide (SiC). They exhibit excellent wear and corrosion resistance, high strength at elevated temperatures, high thermal conductivity, low thermal expansion coefficient, and superior thermal shock resistance. Their application scope has continuously expanded in recent years. In steel production, silicon carbide products are currently used for ladle linings, nozzles, plugs, blast furnace bottoms and bellies, iron troughs, converter and electric furnace tapping nozzles, and waterless slideways in heating furnaces. In non-ferrous metal (zinc, copper, aluminum) smelting, they are extensively used in distillation columns, distillation tower trays, electrolytic cell side walls, molten metal pipelines, suction pumps, and metal melting crucibles.

5.Lightweight Refractories

Lightweight refractories refer to refractory materials characterized by high porosity, low bulk density, and low thermal conductivity. They feature a porous structure (typically 40%–85% porosity) and high thermal insulation properties. These materials serve as insulation in industrial furnaces and other thermal equipment. Compared to standard refractory bricks, they exhibit lower resistance to slag erosion, mechanical strength, and wear resistance, along with significant volume shrinkage at elevated temperatures.

Based on bulk density, lightweight refractories are categorized into lightweight bricks and ultralightweight bricks. Bulk densities ranging from 0.3 to 1.3 g/cm³ classify as lightweight bricks, while densities below 0.3 g/cm³ are ultralightweight bricks.

Based on operating temperature, lightweight refractories are categorized into low-temperature, medium-temperature, and high-temperature types. Materials used at 600–900°C are low-temperature insulation materials; 900–1200°C corresponds to medium-temperature insulation materials; and those exceeding 1200°C are high-temperature insulation materials.

By product form, lightweight refractories are categorized into shaped and unshaped types. Shaped lightweight refractory bricks include clay-based, high-alumina, silica-based, and certain pure oxide lightweight bricks; unshaped lightweight refractories include materials such as lightweight refractory concrete.

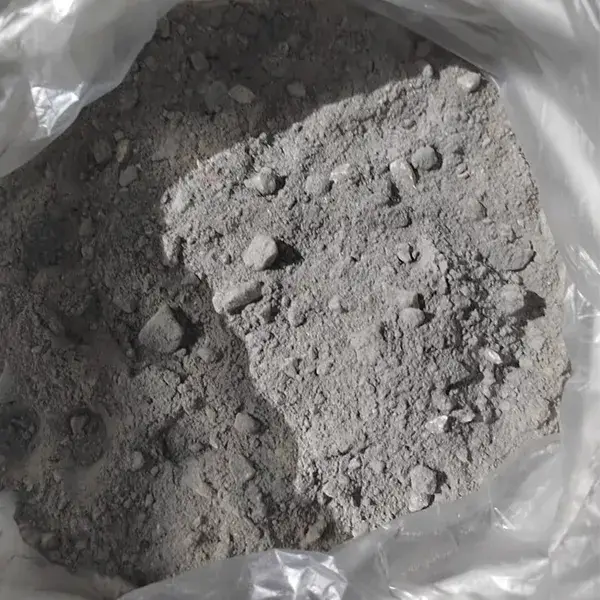

6. Unshaped Refractories

Unshaped refractories are composed of rationally graded granular and powdered materials combined with a binder. They are used directly without molding or firing. Typically, the granular material forming this type of material is called aggregate, the powdered material is called admixture, and the binder is called cement. These materials have no fixed shape and can be made into slurry, paste, or loose forms, hence they are collectively referred to as loose refractories. These refractories can form seamless monolithic structures, hence they are also called monolithic refractories.

There are numerous types of unshaped refractories with various classification methods. Generally, they can be categorized by chemical composition into basic refractories, acidic refractories, and neutral refractories; by chemical composition into silica-based, aluminosilicate, alumina-based, magnesia-based, silicon carbide-based, and alumina-carbon types; By bonding method, they can be categorized as cement-bonded, chemically bonded, or cohesive bonded; by installation method, they can be classified as castables, plastic refractories, ramming mixes, sprayed refractories, and precast components.

Refractories used in the steel industry account for approximately 70% of the total refractory consumption. The primary function of refractories is to withstand high temperatures, abrasion, and corrosion, thereby protecting the structural integrity of thermal equipment and providing optimal operating conditions.