Silica Ramming Mass is an essential refractory lining material used in induction furnaces for melting and holding operations. Known for its high refractoriness, the material is capable of withstanding elevated operating temperatures, making it suitable for demanding furnace environments. Its thermal stability supports consistent performance under heat stress, while its resistance to corrosion from steel and slag contributes to extended lining life when used under proper operational conditions. The material’s electrical characteristics also aid in minimizing the risk of furnace short-circuiting during standard usage.

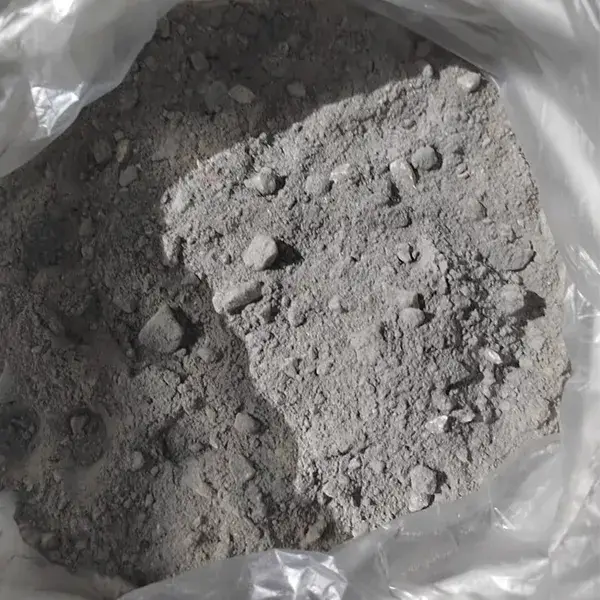

Silica ramming mass is a refractory material that is used to line induction furnaces in the steel industry. The material is made up of high-grade silica and various additives that improve its thermal stability and resistance to thermal shocks. The primary function of silica ramming mass is to protect the furnace lining from the high temperatures and corrosive environment of molten steel, ensuring a longer service life for the furnace.

Silica Ramming Mass Application:

- Induction furnaces for steel, iron, and alloys

- Electric arc furnaces

- Ladles and tundishes in steel plants

- Glass tank furnaces

- And other high-temperature industrial equipment

Silica Ramming Mass is a high-performance refractory material designed to withstand extreme thermal conditions in various industrial applications. As a vital component for lining induction furnaces, electric arc furnaces, and other high-temperature equipment, our Silica Ramming Mass ensures optimal performance and durability.