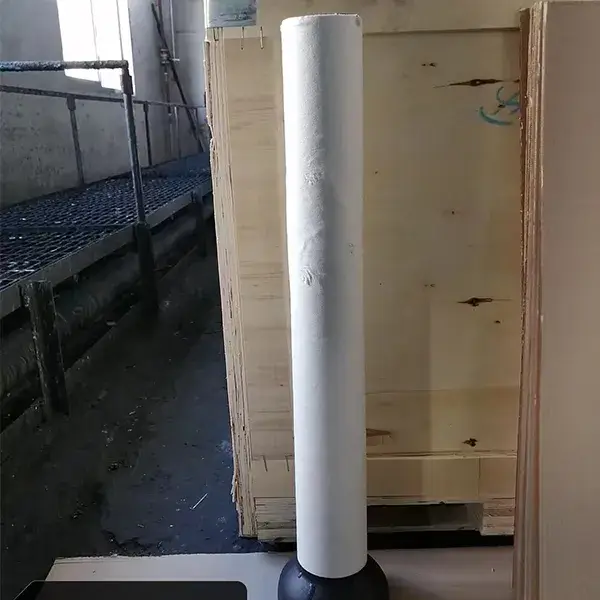

Long nozzle is the connection part between steel ladle and tundish. Head end of long nozzle connects to steel ladle down nozzle, bottom end embeds into tundish steel liquid. Long nozzle can keep steel liquid from contacting with air during transferring from ladle to tundish, so steel liquid won’t splash, impurity won’t enter into steel liquid. The working condition suggests that long nozzle should not only endure strong thermal shock, steel liquid scouring and corrosion, but also suffer the corrosion of tundish cover flux. With the increasing requirement on steel quality, protecting casting ratio is continuously growing, so long nozzles using ratio is surging.

Long Nozzle Application:

The “three major parts” of continuous casting refer to the long nozzle (also known as the ladle protection sleeve) between the large ladle and the medium ladle, the stopper rod, and the submerged nozzle between the medium ladle and the crystallizer. The functions of the long nozzle and the submerged nozzle are to guide the flow, prevent the splashing and oxidation of molten steel, and adjust the flow state of molten steel. The bowl of the long nozzle is connected to the lower nozzle of the ladle sliding nozzle. Due to the rapid flow of molten steel, negative pressure is generated at this place and air is sucked in, causing the molten steel to be secondary oxidized to form mixed and contaminated molten steel.

The long nozzle features a variety of remarkable product characteristics. In terms of structural design, it has a unique slender tubular shape. This design significantly reduces the contact opportunity between the molten steel and the outside air when the molten steel is being poured, strongly suppressing the secondary oxidation of the molten steel and ensuring that the molten steel remains in a state of high purity. Regarding the flow guiding performance, a precise and rational internal flow channel has been constructed. It enables the molten steel to flow smoothly, steadily and evenly towards the tundish along the predetermined path, ensuring the stability of the molten steel flow during the transmission process and effectively avoiding subsequent continuous casting problems caused by flow fluctuations. In terms of impact resistance, the long nozzle has excellent toughness and strength. Even when facing the strong impact force generated when the molten steel is poured rapidly, it can firmly “hold its ground”, maintaining its structural integrity without cracking, deformation and other conditions, safeguarding the continuity and stability of the continuous casting process. In addition, the long nozzle also exhibits good airtightness, tightly blocking the invasion of outside air, further consolidating the purity of the molten steel and improving the final quality of the steel products.