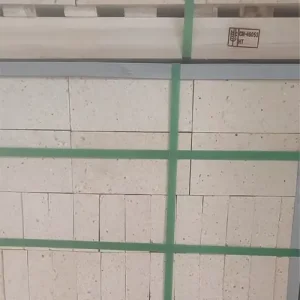

Clay bricks are primarily composed of clay minerals, such as kaolinite, illite, along with various additives like montmorillonite, sand and shale. The production process begins with the excavation of raw clay, which is mixed with water to form a malleable clay mixture. This mixture is moulded into brick shapes through various methods like moulding or extrusion. Subsequently, the bricks are dried and fired in kilns at temperatures ranging from 900 to 1,200 degrees Celsius, a process known as firing or vitrification, which strengthens the bricks and enhances their durability. Clay brick is a type of brick manufactured from fine-grained materials, primarily hydrated silicates of aluminum, which is soft and cohesive when moist but hardens when baked or fired.

Clay Brick Advantages:

One of the notable properties of clay bricks is their excellent thermal insulation capabilities. Their low thermal conductivity helps regulate indoor temperatures by minimizing heat transfer, thus reducing energy consumption for heating and cooling.

- High density bonded SiC material

- Excellent strength and erosion resistance at operating temperatures

- Thermal shock resistance

- Engineered shapes

- Proven performance

- Long service life Increased reliability in the most critical part of the furnace

- Easy installation

- Reduced maintenance